MODULAR CONSTRUCTION

System assemblies.

Partnering with us for system assemblies allows you to benefit from modular design in mechanical and plant engineering.

By combining standalone solutions into one installation module, we generate a larger volume and can use additional connection technology solutions.

By replacing expensive terminal technologies with printed circuit board solutions, we can create simple and convenient connections to the peripherals. We take the existing system design into account and adapt all forms of our modules to the circumstances.

This is made possible by our team and our experience.

Your advantages.

Our spectrum.

- Up to 30% less costs

- Drag chains, cables, connectors, cable glands together with structural steelwork – from a single source

- Shorter lead time in final installation

- Less administration – one order, one good inspection, one picking

- Less products stock

- Bulkhead-type end connections or cord sets assembled with claddings as a prefabricated sub-system

- Concept and design of the installation modules

- Including fluid installation, electronics and shaping of sheet

- Delivery of installation modules ready for mounting

THIS IS HOW IT’S DONE

Case Studies.

MANUFACTURING TECHNOLOGIES

A turnkey solution from a single source thanks to our production techniquesn.

Partnering with us for installation modules allows you to benefit from modular design in mechanical and plant engineering.

By combining standalone solution into one installation module, we generate a larger volume and can use additional connection technology solutions.

By replacing expensive terminal technologies with printed circuit board solutions, we can create simple and convenient connections to the peripherals. We take the existing system design into account and adapt all forms of our modules to the circumstances.

This is made possible by our team and our experience.

1

Cable assembly

We manufacture a wide range of standardised and tailor-made cable assemblies for mechanical engineering, medical technology, renewable energies and mobile automation.

Pneumatic and hydraulic assembly

Different media are combined today into mechatronic systems. For this reason, we also assemble tubes and hoses for your pneumatics and hydraulics.

2

3

Layout of printed circuit boards

Often it makes sense to replace terminals with appropriate low-cost interface modules in order to ensure working consistently with 100%-tested cable assemblies. We take over the layout of the required printed circuit boards.

Printed circuit board assembly

If printed circuit boards are used, we guarantee production on modern assembly and selective soldering machines – for reliable processes and an efficient overall solution.

4

5

Mechanical processing

In many cases, mechanical drawing parts made of different materials such as steel, aluminium or plastic are important components of an installation module. We will draw and turn or mill these parts for you.

Sheet metal machining

Drawing parts can also be sheet metal structures made of steel, stainless steel and aluminium. This includes custom switch boxes, machine panels, bulkhead plates, etc. We take on the challenge of producing them professionally.

6

7

Machine frames

Often it makes sense that a part of a machine or plant frame is included in the scope of delivery of an installation module. It doesn’t matter if it is a welded design or constructed out of pre-assembled system components; we deliver the complete package.

Surface technology

Whenever mechanical drawing parts, sheet metal parts or machine frames are part of our scope of supply, a suitable surface technology must also be guaranteed. This is achieved through our many years of close cooperation with specialist companies from electroplating, painting technology and powder coating.

8

Would you like personal advice?

Our product expert Christian Gladis will be happy to advise you. Together we will find the right connection for you.

ALWAYS WELL INFORMED

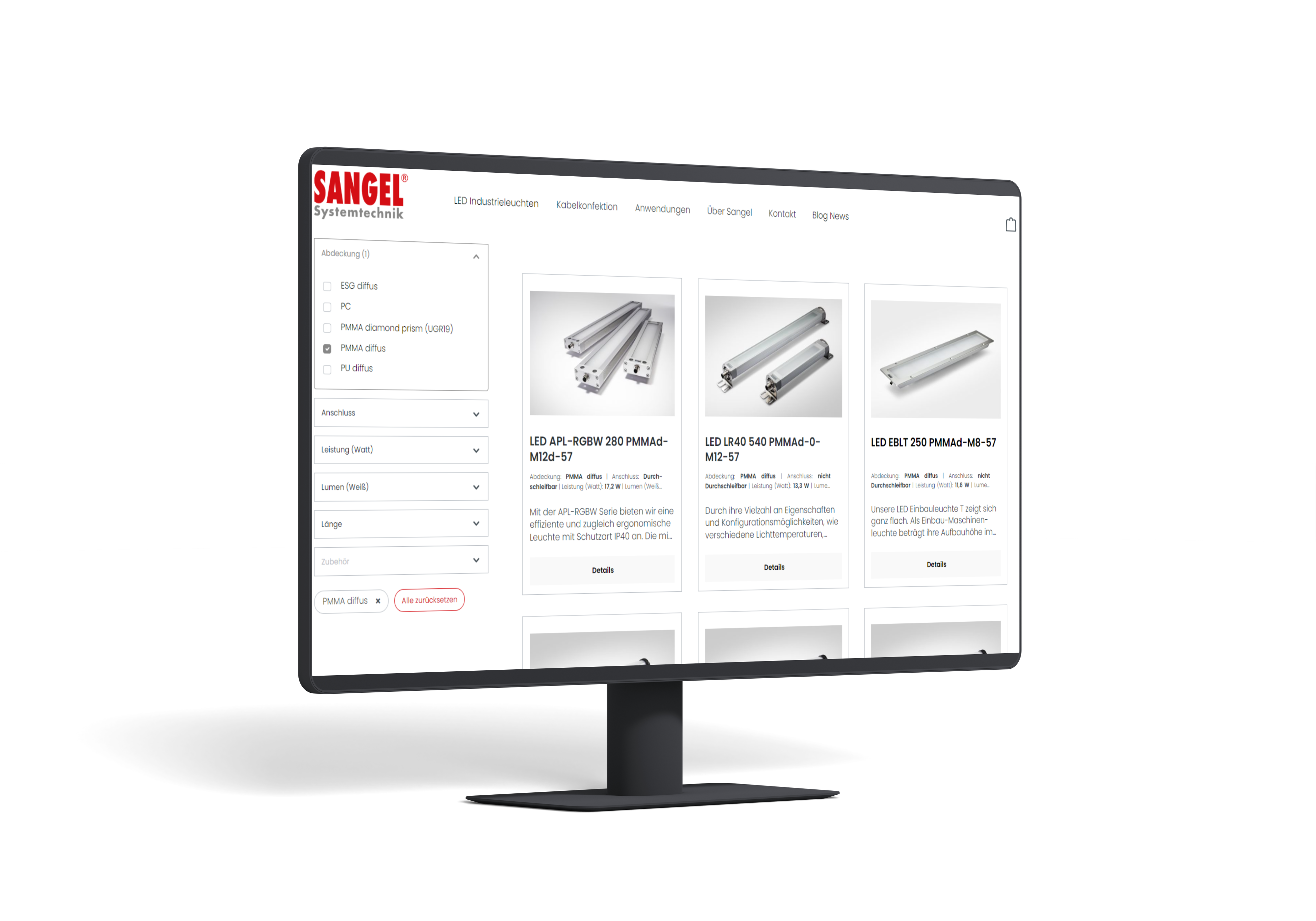

Our download centre.

Download the catalogue for your drive system now.

Here you can download our current brochures in the areas of drive systems, LED industrial luminaires, Original Equipment Manufacturer and system assemblies, as well as the current delivery and payment conditions and purchasing conditions of SANGEL® Systemtechnik GmbH as pdf documents. pdf documents.