MANUFACTURED TO MEET YOUR REQUIREMENTS

LED customised solution.

Due to the increasing complexity and individuality of machines, the technical requirements and design demands on the systems and their components are growing.

Lighting and signaling are becoming increasingly important. As a fixed component integrated into the machine, they increasingly serve as a design tool or contribute to safe processes by visualizing information. A standard product often does not meet all lighting, mechanical and interface-related requirements at the same time, and our strength lies in finding a solution for you that does just that.

We have access to a wide range of standard products and many years of experience, so that a completely new development is not absolutely necessary for your solution. This saves you valuable time and money.

Your advantages.

Our scope.

- Modification of existing products or complete new development

- Customized, suited exactly to your needs

- Attractive pricing from medium quantities

- You determine the product, we develop it

- Development of customized circuit boards

- Customized housing dimensions and materials

- Diverse cover materials

- Customized fastening elements

- Different light temperatures

COMPACT OVERVIEW

Our portfolio of LED machine luminaires.

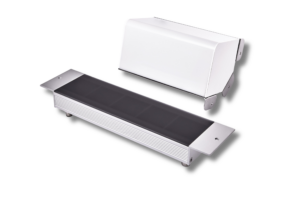

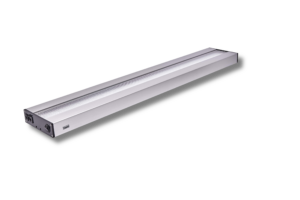

Our range of LED machine luminaires includes recessed luminaires, surface-mounted luminaires and signal luminaires. Our surface-mounted machine luminaires are suitable for different beam angles and impress with their flexible mounting options. Simultaneous illumination and signaling is possible with our LED machine luminaires with signal function. Our LED recessed luminaires impress with their flat design and are particularly suitable for small installation spaces.

LED LIGHTING GUIDE

10 steps to the right LED machine luminaires.

We have summarized the most important questions from many hundreds of customer discussions for you in a compact guide so that you can complete your next project even more successfully.

1

Keeping an eye on costs right from the start

The ever-increasing competitive pressure means that machines have to be developed and built more and more cost-efficiently. This guide helps you to keep an eye on all the important points for cost-optimized engineering of a luminaire system right from the start.

Together from the start!

Take time for a kick-off meeting to agree the following points together.

Every department has its own requirements for such a project. Defining the framework conditions from the outset provides security for everyone involved and thus leads to a successful project completion.

2

3

Define IP protection types

The IP protection classes can be a major price driver for a lighting system. It is therefore important to determine at the outset what requirements you have in this area. The protection classes should also not be set too high. It is not uncommon for high protection classes to be set out of “pure habit”, even though the ambient conditions would not require this.

What operating voltage?

24V or 230 V – this question should be clarified from the outset. Most LED machine lighting systems are designed for an operating voltage of 24V. However, a voltage of 230 V can also be relevant, depending on the framework conditions you specify in your electrical installation. Specify this at an early stage.

A subsequent change is often not possible.

4

5

Light color and color fidelity

The light color as well as the color fidelity are important decision criteria for optimum illumination in your machine. Light colors between 5700 and 6500 Kelvin have established themselves as standard. This puts you in a range that is always close to daylight white. The color fidelity value should be Ra / CRI ≥ 80 so that natural color rendering can be guaranteed.

Power vs. illuminance

Watt values only provide a rough guide. The decisive factor, however, is the actual illuminance of a machine light. Many manufacturers indicate “E-medium” and “E-max” as guide values. These values are the result of a simulated laboratory measurement. An area of 100cm x 100cm is illuminated. The luminaire is suspended at a height of 100 cm.

6

7

How much space is needed?

A crucial question that should be considered from the outset. Depending on the desired illuminance, the housing sizes vary in the range of several 100 millimeters. Sufficient space should therefore be planned in the machine design for the light. Our experience has shown that subsequent changes can lead to considerable additional costs in machine development.

Mounting options

This is also a crucial question and has involuntarily prolonged many a development phase. Make sure from the outset that the mounting options for the luminaire match your machine design. Subsequent changes or even the forced selection of a different type can quickly lead to considerable additional costs.

8

9

Ambient temperatures

A crucial question that should be considered from the outset. Depending on the desired illuminance, the housing sizes vary in the range of several 100 millimeters. Sufficient space should therefore be planned in the machine design for the light. Our experience has shown that subsequent changes can lead to considerable additional costs in machine development.

Standards and approvals

The international mechanical engineering market has very different requirements in terms of the regulations to be observed in each country. UL, CSA or special approvals in the food & beverage sector should play a central role in the selection of the machine light.

10

Would you like personal advice?

Industrial luminaires for optimum machine lighting or optimum lighting at the assembly site are not something you just change. That is clear to everyone. Structural issues need to be clarified for a replacement or modernization. But other changes are also often necessary. We will advise you personally – from the initial inquiry through to installation.

So that your work processes run smoothly.

OUR VALUES

What sets us apart as a manufacturer of LED machine luminaires.

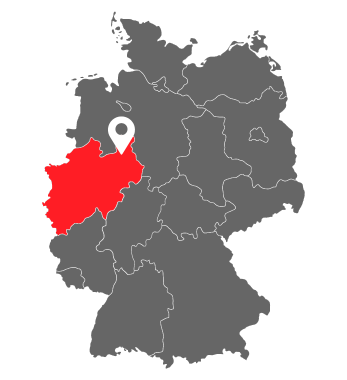

Produced in Germany

As a manufacturer of LED machine luminaires, we have been producing our products in Germany for decades. Every workpiece is manually checked by us at our facility in Bielefeld. We personally carry out all tests such as heat and cold tests, IP and surge tests. This is how we ensure the highest quality for our customers. For maintenance-free LED industrial luminaires with a very long service life.

Customised consultation

Replacing lighting requires discussions and understanding the specific working situation at the machines. The specific design can also play an important role. In a personal consultation, we break down your situation and requirements and work with you to find your optimal machine lighting.

Fair prices

An LED machine luminaire on a machine tool must meet different requirements than a luminaire on a packaging machine. That is why we offer a wide range of combination options – including material, illuminant, cover and design. The result: You will also receive an appropriate, fair price for a suitable luminaire.

ALWAYS WELL INFORMED

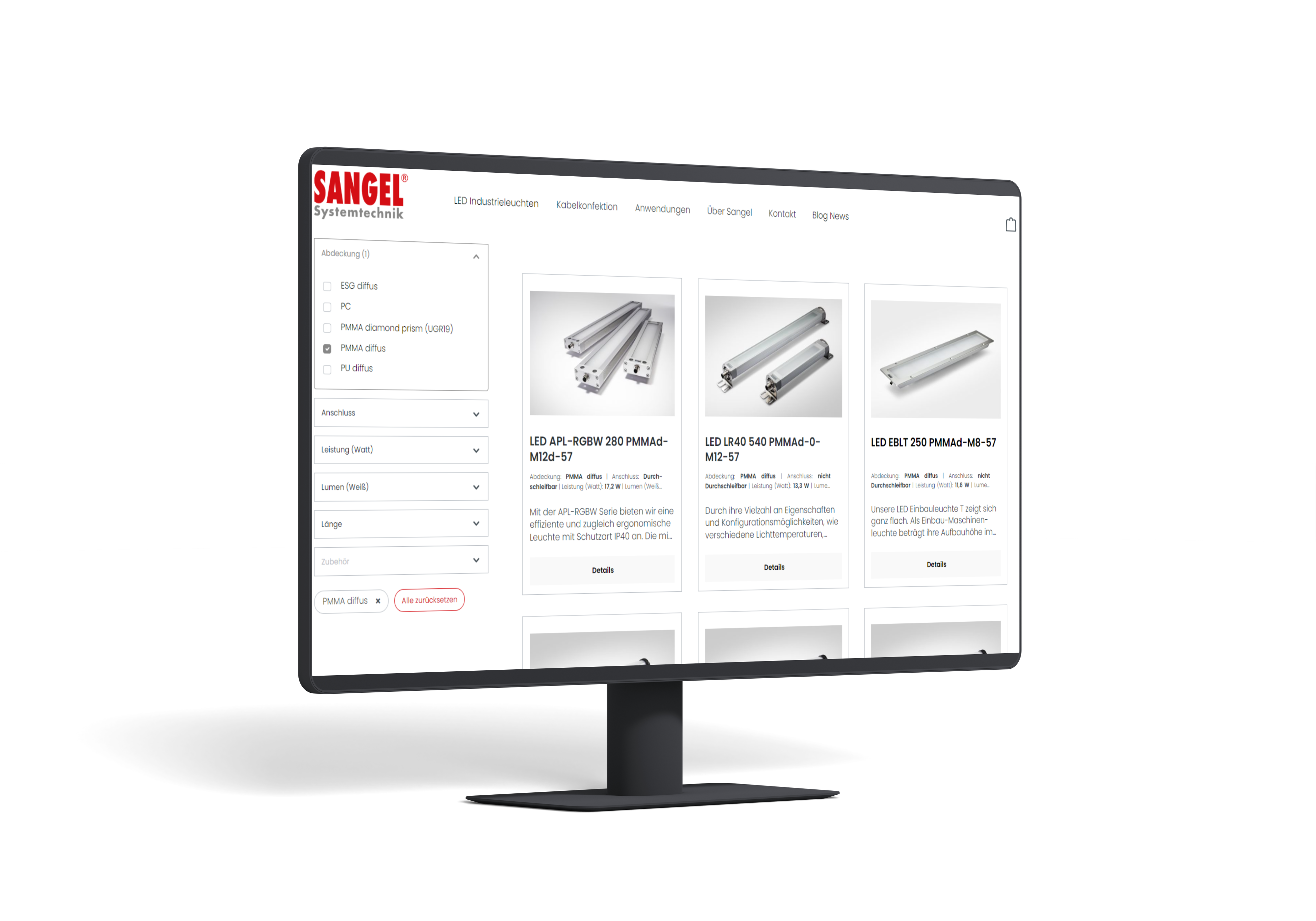

Our download centre.

Download the desired information directly.

Whether LED machine luminaires, LED workstation luminaires, LED signal luminaires or special LED solutions as a modification of existing products or completely new developments:

Find out more about our solutions in the field of machine lighting, workplace lighting or signal lights, including mounting sets, connection cables and extension cables.

You will also find the answers to many questions about the technology of LED industrial luminaires in our detailed glossary.