THIS IS US

About Sangel.

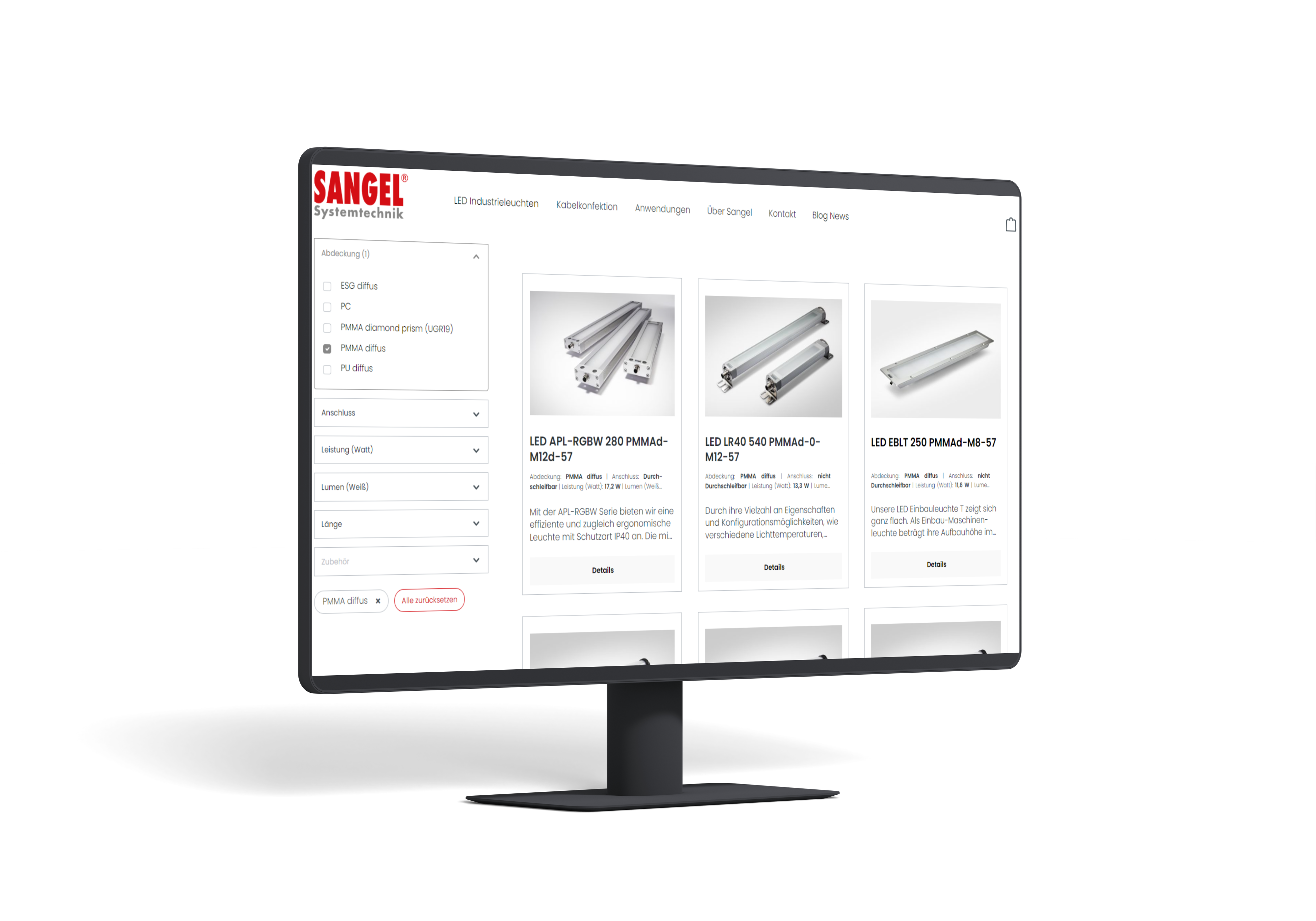

We are a family-owned company and one of the leading suppliers of cable assemblies, industrial LED luminaires and system assemblies for mechanical and plant engineering.

With around 250 employees, we produce in our factories in Germany and Bulgaria and sell our products in over twenty countries worldwide via our international sales organisation.

Since 2022, we have been part of the Helukabel Group, a leading international manufacturer and supplier of cables, wires and cable accessories. Find out more about the Helukabel Group here.

Connecting the world.

Our manufacturing sites.

Our sales locations.

TAKE A LOOK BEHIND THE SCENES – WE INVITE YOU

Behind the scenes.

HUMAN CONNECTIONS

Guiding Principles.

Our relationship to our customers.

The most important thing for us are our customers. That is the reason for our intention to create every customer-relationship as a win-win-situation. The best technical and cost effective solution for our customers is always our ambitious aim. Our strategy to achieve this aim is based on the high educational level and specific knowledge of our staff, on ideal processes in the company logistic, in the consulting, in the development, project planning and in the production. That means that our customers always benefit from our professional know-how and the high quality level of our products in order to achieve financial advantages compared to the conventional method of operating. The basis therefore is cooperation full of respect and partnership and an open and honest communication in order to provide true confidence. If our customers compare our quotations and performance with our competitors, we kindly advise them to do this in a comprehensive, correct and fair way.

Our relationship to our employees.

We wish to have highly qualified, motivated and satisfied employees who feel safe and secure. One of our intentions is to grant this. Although we are not a family company, we act like one. All employees take care of each other. A respectful behavior full of fairness among each other, to our customers and to suppliers is a natural thing for us. Mistakes could happen, because this gives us the opportunity to learn and to grow. Each kind of discrimination is strictly not accepted. We definitely know that the high quality of our products depends on the commitment, the experience and the know-how of our employees. Therefore, as we support them, we also expect high performance. This allows us to achieve an advance in technical know-how and to establish secure and attractive jobs.

Our relationship to our suppliers.

One of the reasons for our success is our motivated suppliers. We know this and of course appreciate it. We always wish to create a long term partnership and a continuous transfer of technology, innovation and know-how. Our special technical and economical requests enable our suppliers to improve their development. The relation to our suppliers is based on honesty, confidence and cooperative behavior.

Our attitude to our competitors.

We appreciate a fair competition with our competitors. We recognize their good performance and respect them. We do not fight against our competitors, instead, we try to bring our own company forward and establish us as one of the best companies in our market. Although our products are used in machineries all over the world, we do not see us as a global player, but as an international system supplier.

ALWAYS IN SIGHT

Future Outlook.

The market position we want to reach

Indicated by quality, innovation and know-how, we want to belong to the TOP3 of our segment. Our products are applied worldwide. Instead of looking at us as a global player, we see ourself as an international system supplier.

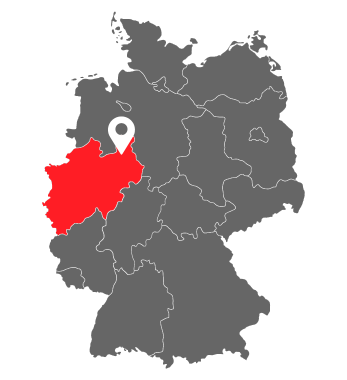

Our commitment to our location

Bielefeld and the area around us is known as a stronghold of the machinery industry. We commit ourselves to this strategically important location and will develop our company growth here.

Our profit will be invested in our future

In order to assure our jobs and our competitiveness we invest our profits into our company. We use our profit for financing our stock level, our continuous development of technical solutions and the improvement of our production processes. In this way we maintain our good position in the market and our entrepreneurial liberty.

MADE IN GERMANY

Certificates.

To be able to deliver a highly qualitative product at the right time to the right place for an appropriate price requires a perfect organisation.

Due to our centralized activities in Bielefeld in which all our processes have been consequently optimized we can achieve highest reliability.

SANGEL® system solutions are strong connections between different components. Strong connections are also generated by memberships, which create close contacts to the machine building field.

DIN ISO 9001 – 2015.

UL – Wiring Harness.

Membership VDMA.

Membership OWL Maschinenbau.

Apprenticeship.

OUR HISTORY

Milestones.

1996

Founded as a trading company for connectors, cables and cable assemblies

1998

Setting up your own production

2001

Acquisition of your own company property

2003

Certification according to DIN ISO 9001:2000

2014

Start of in-house production of industrial and machine luminaires

2017

Inauguration of the new 1,000m² production facility for cable assemblies in Bulgaria

2018

Moving into the new headquarters in Bielefeld

2022

Takeover by the Helukabel Group