ILLUMINATE AND SIGNAL AT THE SAME TIME

LED Signal Luminaires.

The use of color has served as the international language for signaling a condition in almost every industry. Signaling towers are the most common method used for signaling information but are quickly rendered useless when installed out of sight.

Currently, we have observed the trend shifting towards the installation of these signaling devices inside the actual machine room/enclosure or on the front of the machine; resulting in process stability and optical clarity.

It became very clear to us, early in the design and engineering stages, that the combination of the white light and RGB belonged in a single casing to allow for efficient cable management and to help reduce material usage. The marketplace agreed with us and the all-in-one luminaire design quickly became a huge hit with numerous high-profile companies installing and standardizing on our RGB-machine lighting.

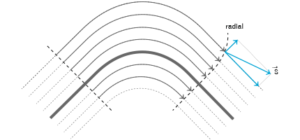

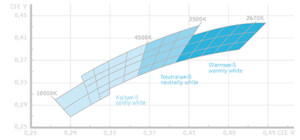

We combine white LEDs with RGB-chips, which we choose by their low binning tolerance; resulting in a minimal spread of light temperature and ensuring optimal light distribution. Apart from the six different RGB-colors, our RGBW-luminaires offers up a pure, white light with a CRI>80.

Additionally, we offer a solution with individually controllable RGB-chips for displaying progress or optical operator guidance.

Benefits to you.

Our spectrum.

- on site for you in over 40 countries – 30 experienced partners only in Germany

- 80% of our LED industrial luminaires are available from stock

- State-of-the-art energy efficiency

- Maintenance-free – no need to replace light sources

- LEDs with quality – exclusively from reputable manufacturers

- 60,000 hours guaranteed service life

- Innovative customised solutions

- UL certified LED machine luminaires

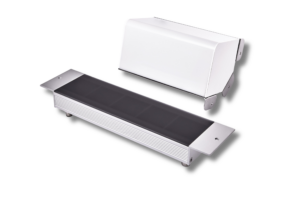

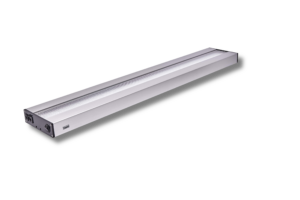

- Compact, recessed, surface-mounted, line and panel luminaires

- Illuminating and signalling

- Rotatable or fixed mounting

- Cover made of toughened safety glass (ESG) or plastic (PMMA)

- Connection via industrial standards (M8/M12)

- Fixed or flexible voltage range

- Dimmable (PWM, analogue)

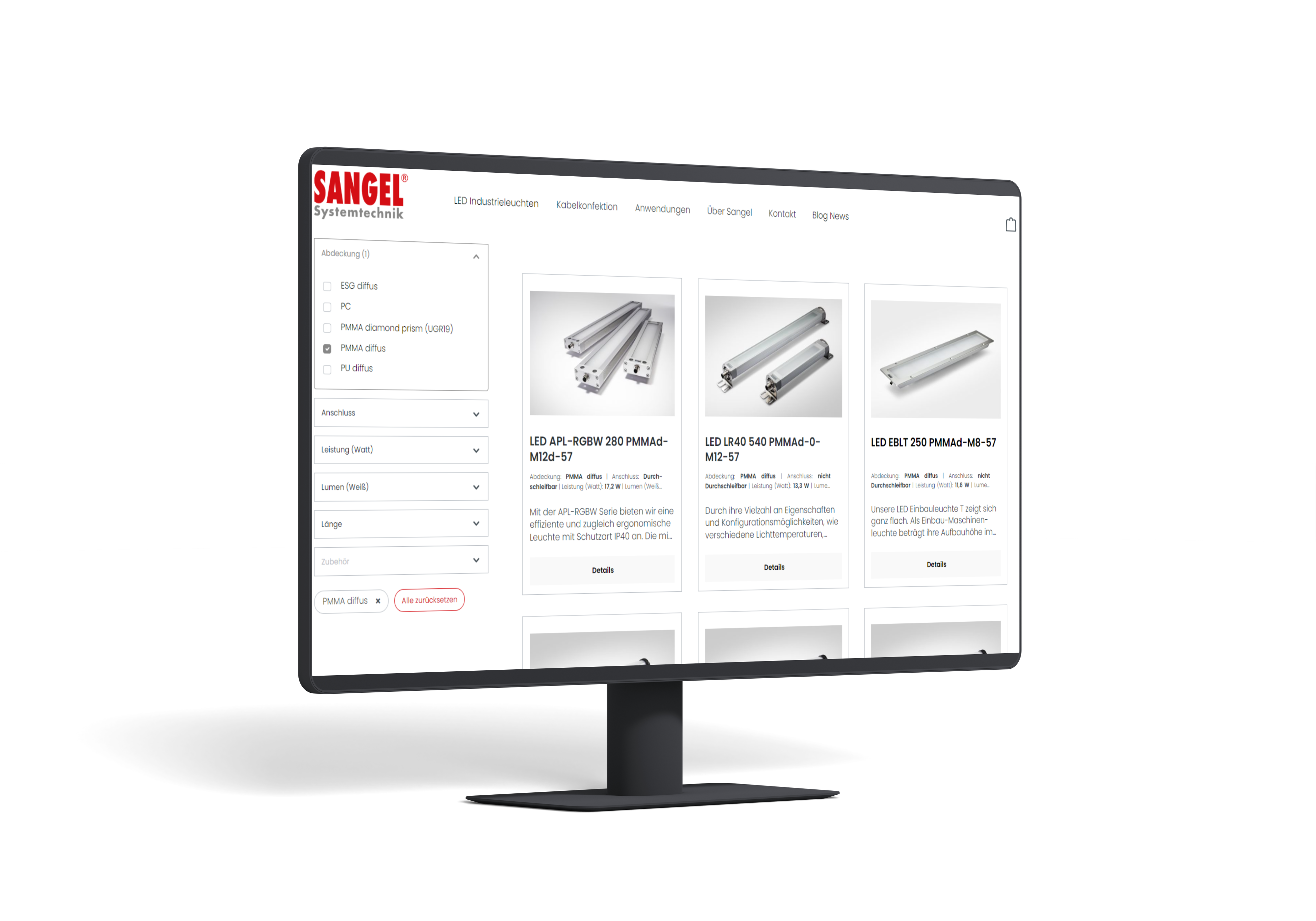

OUR PRODUCT PORTFOLIO

LED machine luminaires as a surface mounted version.

SMART SOLUTIONS

Intelligent LED machine luminaires.

Due to the increasing complexity and the individuality of today’s machines, signaling and lighting are taking up an ever-increasing role of serving as an integrated design component and as a means of optimizing specific processes through the visualization of information.

Though our offerings extensive, standard product do not always fulfill all your mechanical, photometric and interface requirements; therefore, a customized product is sometimes the only possible solution. Why are we the right partner in these cases?

Because of our extensive experience and exposure to the vast projects we have undertaken with our clients to ensure their individual requirements were met with customized and unique solutions, and thanks to the success of these specialized projects, we can now share this experience with you to help you achieve a custom solution quicker and more cost effectively.

ALWAYS WELL INFORMED

Our download centre.

Download the desired information directly.

Whether LED machine luminaires, LED workstation luminaires, LED signal luminaires or LED special solutions as a modification of existing products or completely new developments:

Find out more about our solutions for machine lighting, workplace lighting or signal lights, including mounting sets, connection cables and extension cables.

You will also find the answers to many questions about the technology of LED industrial luminaires in our detailed glossary.

OUR VALUES

What sets us apart as a manufacturer

of LED machine luminaires.

Produced in Germany

As a manufacturer of LED machine luminaires, we have been producing our products in Germany for decades. Every workpiece is manually checked by us at our facility in Bielefeld. We personally carry out all tests such as heat and cold tests, IP and surge tests. This is how we ensure the highest quality for our customers. For maintenance-free LED industrial luminaires with a very long service life.

Customised consultation

Replacing lighting requires discussions and understanding the specific working situation at the machines. The specific design can also play an important role. In a personal consultation, we break down your situation and requirements and work with you to find your optimal machine lighting.

Fair prices

An LED machine luminaire on a machine tool must meet different requirements than a luminaire on a packaging machine. That is why we offer a wide range of combination options – including material, illuminant, cover and design. The result: You will also receive an appropriate, fair price for a suitable luminaire.

FAQ — LED MACHINE LUMINAIRES

Frequently asked questions.

We need a 24V LED machine luminaire, do you have this in your range?

We offer LED luminaires in all protection classes. This also includes 24V LED luminaires with, which fall into protection class III and are thus supplied with protective extra-low voltage. The supply voltage is thus so low that there is no danger from it. 24V LED machine luminaires are used, for example, when working with water.

Which machine tools are your LED machine luminaires used for?

Our LED luminaires are used in a wide variety of machine tools. These include CNC lathes, CNC milling machines, CNC grinding machines or in CNC machining centres. Flying chips, the use of coolants and lubricants in the vicinity of the LED machine luminaire are the norm. We have the right solutions for you for precisely such requirements.

Which LED machine luminaires are suitable for packaging machines?

For packaging machines, the requirements for luminaires are generally lower than for workplaces where high heat and water are used. Protection against dust, for example, is often sufficient. This also has an impact on the price. Here we have specific and cheaper products in the range such as the ELN and SLN solutions.

Which LED machine luminaires are suitable for the food industry?

Machines in the food industry need to be cleaned frequently. The machine luminaires must be protected accordingly. This is recorded in the protection class in the second code number. This concerns protection against ingress of splashes, drips, sprays and jets of water as well as submersion. Thus, we are happy to offer you LED machine luminaires with protection class IP69K as a solution.

Machine luminaire or machine lamp: Is it the same?

The term machine lamp is often used as a synonym. But a lamp is only the illuminant. The luminaire is the overall construction. This also includes an LED machine lamp.

Further questions about the technology of our LED machine luminaires?

You will find answers to many other questions about the technology of our LED machine luminaires in our detailed glossary.

LED TECHNOLOGIE

Three advantages of LED technology in our machine luminaires.

1

Long performance

LED industrial luminaires have a very long service life. If the light intensity falls below 70 percent, the service life is considered to have expired. In 3-shift operation over five days per week, we guarantee a luminosity of over 70 % for 9.6 years. One reason for the long durability is our design: We work with aluminium core circuit boards. They conduct the heat into the environment via the luminaire housing. As a result, heat generation is significantly lower, which has a positive effect on durability.

Good colour rendering

For illumination at the workplace, you need good colour rendering and a uniform colour temperature. This prevents fatigue at the workstation. Our LED industrial luminaires reach a value of more than 80 percent in the colour fidelity index. The diodes are clustered in a CIE standard colour system, known as binning.

2

3

Flexible dimming

Many models of our LED industrial luminaires have an eco mode. This dims the illumination and still emits 30 percent of the luminous flux of normal operation. Machine workstations can thus be made even more ergonomic. When the interior is accessed, the luminaire displays its full brightness. While using the machine interior, it only lights up discreetly. This ensures optimal machine lighting at all times.