ARE YOU READY?

Your future in #team SANGEL.

Take your first step into the world of work and learn an interesting apprenticeship at a medium-sized, globally active company with good prospects for your future career!

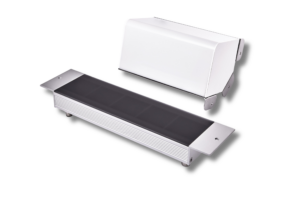

At Sangel, we offer the following apprenticeships:

– Industrial clerk

– Warehouse specialist

– Warehouse logistics specialist

YOUR APPRENTICESHIP

Open training positions.

Just check back here regularly to find out which apprenticeships are currently available.

We are looking for you for training from August,1 2025

Duration of the apprenticeship: 2.5 years

Industrial clerks work in industrial companies in a wide range of sectors. They take on business management tasks in core commercial functions such as marketing and sales, procurement and stockpiling, service accounting or human resources.

We offer you

- A job in an expanding company

- A company that is prepared to invest in itself and its employees

- A great team that challenges and supports each other

- A great exchange with trainees from other apprenticeship years

Your profile

- University entrance qualification or comparable

- University dropout

- Vocational school qualification

- Car driving licence

- Commercial interest and sense of responsibility

- Affinity with numbers and data

- Good communication and negotiation skills

How do you apply to us? It’s very simple!

Write to our training manager Julia Haarstrick in three to four sentences explaining why YOU are the right person for our apprenticeship and convince us with your motivation, including your CV.

We look forward to hearing from you!

Julia Haarstrick

HR Office and Training Manager

We are looking for you for training from August,1 2025

Duration of the apprenticeship: 2 years

Warehouse specialists accept goods and check the type, quantity and condition of deliveries based on the accompanying documents. They record goods, sort and store them. They check stock levels at regular intervals and carry out inventories. They pack goods for dispatch, fill out the accompanying documents and load lorries. They mark, label and secure consignments.

We offer you

- A job in an expanding company

- A company that is prepared to invest in itself and its employees

- A great team that challenges and supports each other

- A great exchange with trainees from other apprenticeship years

Your profile

- Secondary school leaving certificate or equivalent

- Interest in your work and a sense of responsibility

JOIN THE TEAM

Many good reasons for #teamSANGEL.

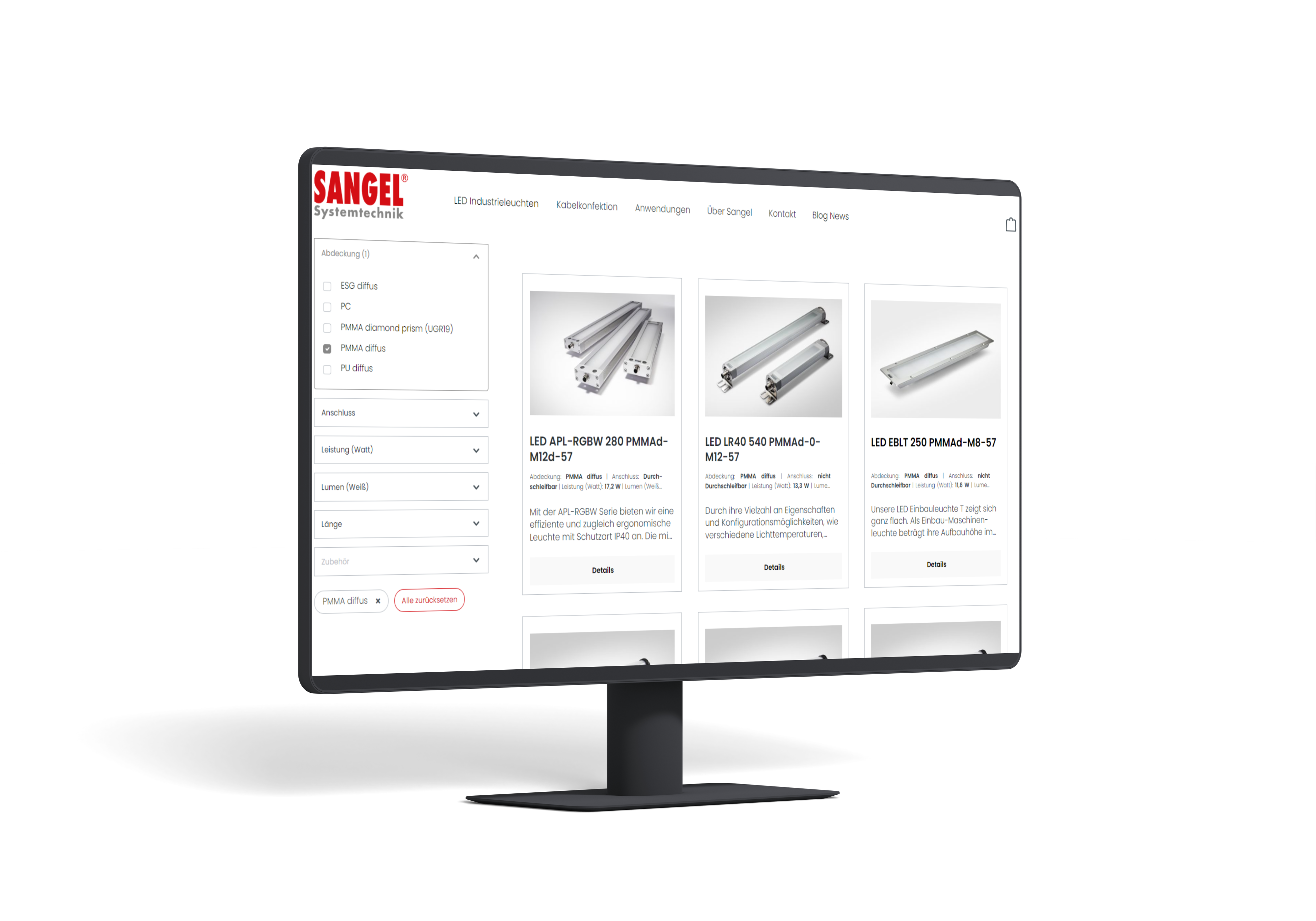

- Autonomy and independence as a family-run company

- Member of the HELUKABEL group of companies

- International presence with 2 production sites and representatives in more than 30 countries

- Outstanding quality of employee training and further education

- Respect, social responsibility, transparency and sustainability are important to us